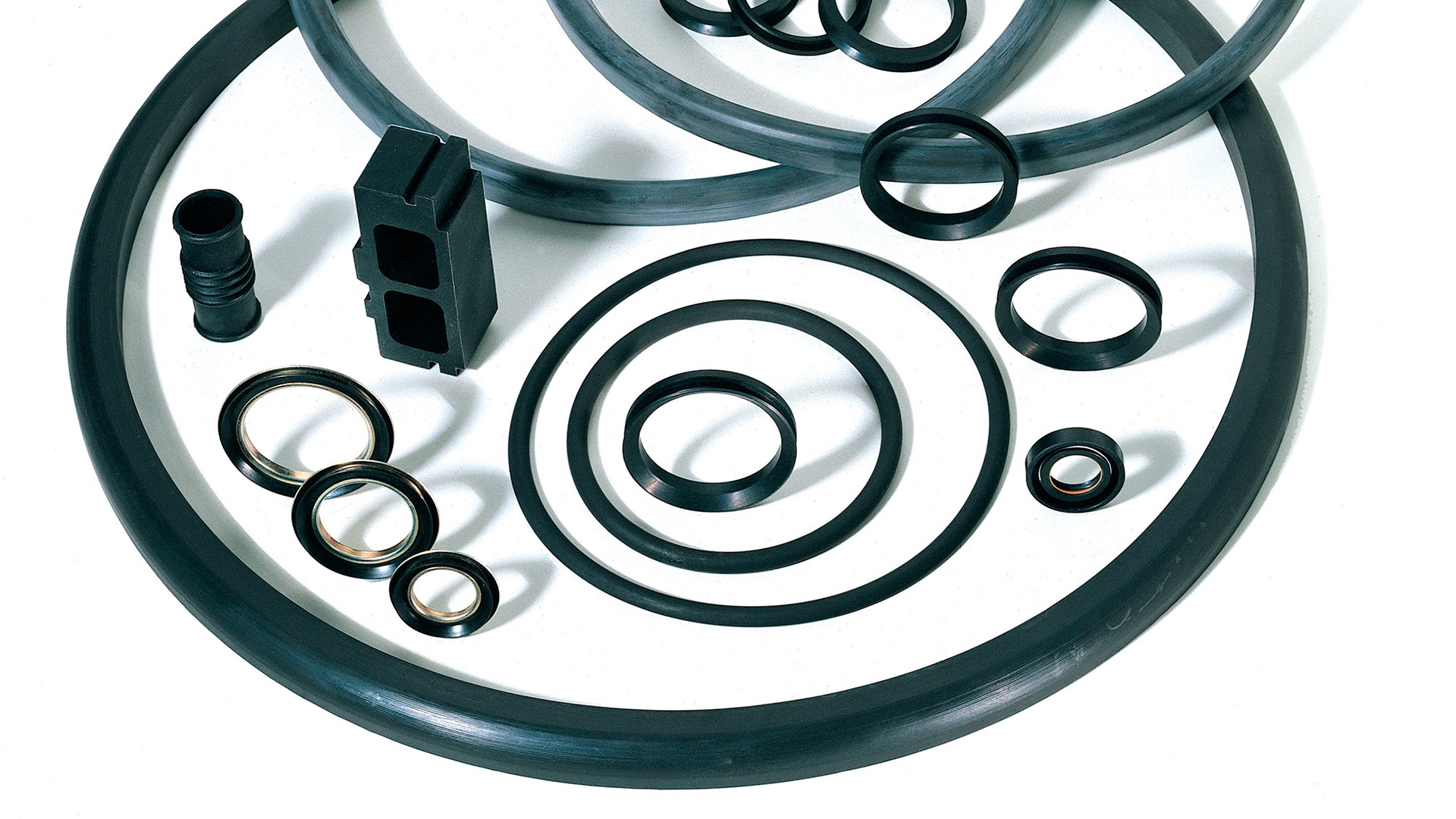

From the finest precision seals to the largest heavy duty shaft seals and packings Our products address the needs of customers that wish to have a broadGroove dimensions on pages 30 and 31 to decide what is the closest size 'O' Ring, again bearing in mind the points made in section 1 3) If you are at the design stage there are a multitude of considerations, but try to keep your selection simple As far as possible choose exstock sizes and material Only specify exotic or completely nonstandards if you have no other choice Keep toA chart listing the most popular compounds and their fluid compatibility / technical information Learn More > ORing Groove Design ORing Groove design plays an important part in how an oring seals Learn More > Contact World Class;

1

Size chart o ring groove dimensions pdf

Size chart o ring groove dimensions pdf-ORING REFERENCE AS568 SIZES 1 Oring tolerance stackup) and the smallest possible Oring in the largest possible groove Throughout this reference guide the term "compression" is used for describing what provides the sealing force Since elastomers are essentially incompressible, the technically correct term would be "deformation" Compression is used, as it is the more0045" for 4 – 6";

Dynamic O Ring Design Chart Marco Rubber Plastics Custom O Rings Supplier

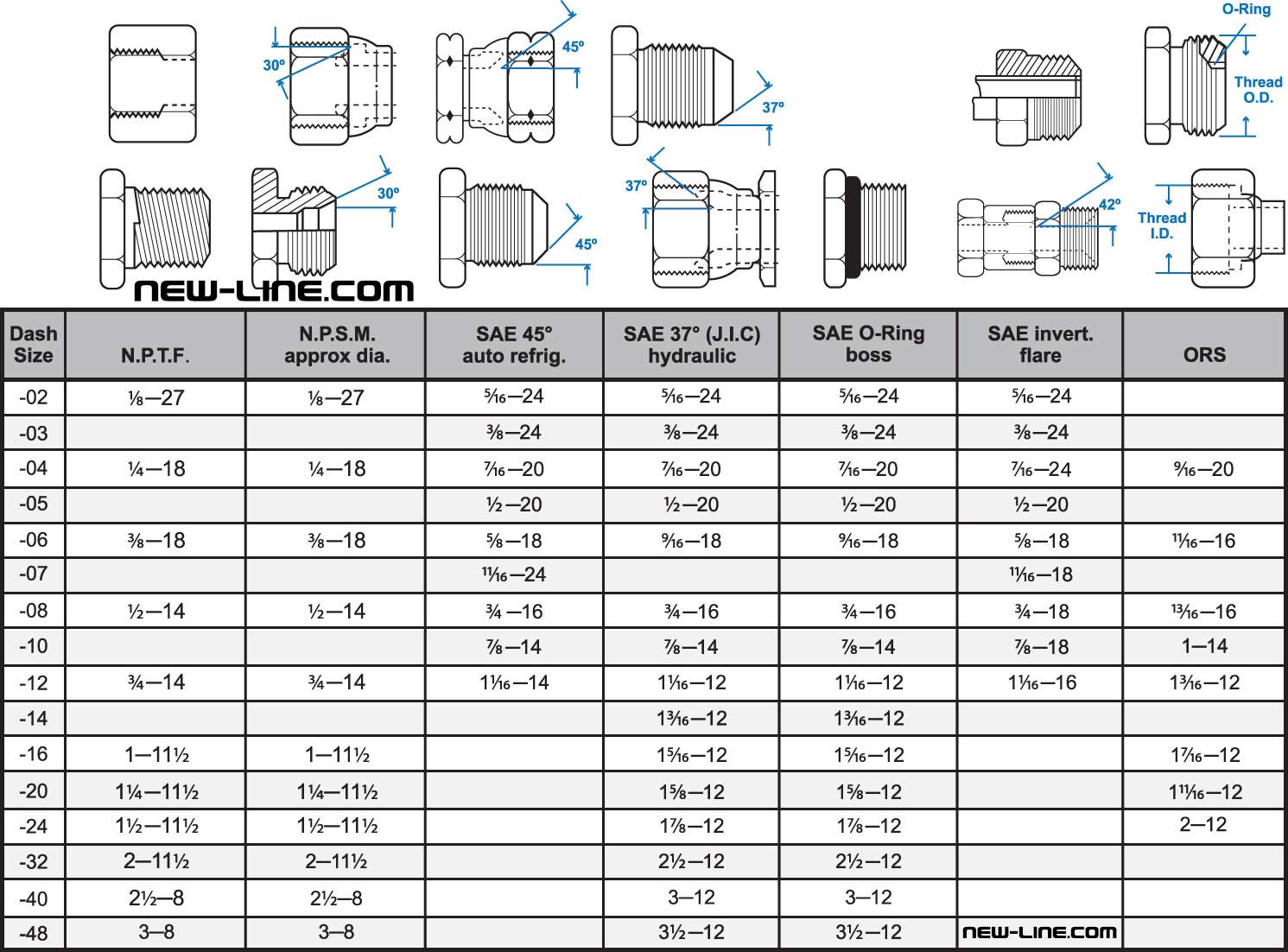

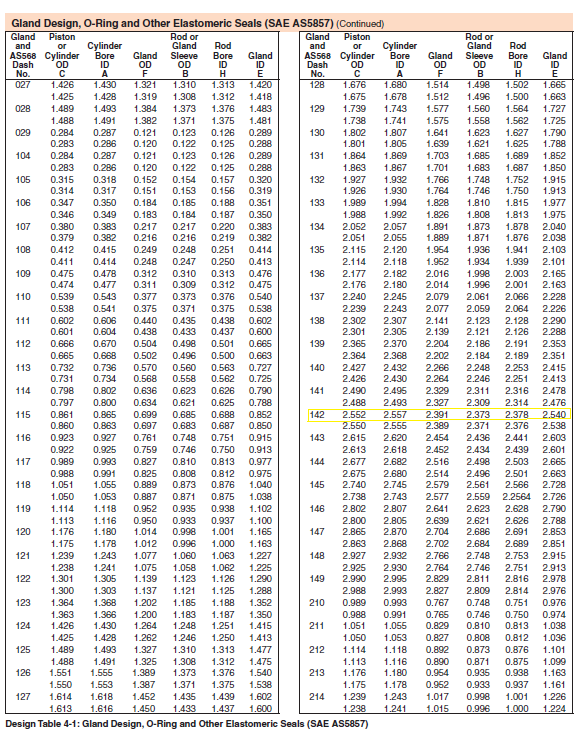

Shortly after ORings first came into common use, it became obvious that standards for ORing sizes, tolerances, and groove design would be beneficial The first standards were issued in 1942 Since then various government and engineering organizations have produced a multitude of ORing standards From this large list we chose to include the following national and international OThe main advantages of small Oring crosssections incorporate a smaller compact size, lighter weight than larger crosssection Oring's, and are less expensive especially in reference to higher cost elastomers like FKM or fluorosilicone With a smaller crosssection there is less machining required for machined grooves since the groves are smaller Smaller crosssection Orings areORing Seal Sizes NOT all sizes readily available in all materials For quotes, prototypes or questions, call ORing Seal Sizes For quotes, prototypes or questions, call ORing Seal Sizes NOT all sizes readily available in all materials For quotes, prototypes or questions, call Bold type denotes Standard AS568 Please check

ORings Dimensions & Illustrations wwwPrecisionAssoccom In order to assure size accuracy, make sure that Page Scaling is set to NONE prior to printing this document Change this setting by selecting File, Print Page Handling Page Scaling None After printing, verify that size is correct by chec king scale on printed page Precision Associates, Inc Phone (612) 3800 NSecond Pick the series Oring desired, based on the thickness of the flange available to cut the groove depth desired (I244) Third Check the swell characteristics of the fluid on the rubber to determine whether the normal or high swell chart will be used for dimensions of the Oring groove (In this case 015% or normal swell Chart I)Review the general oring groove design considerations before moving onto the specific oring gland design type Engineering support services are available for a fee for expert help optimizing critical applications Once your design is complete, easily order orings online from the world's largest oring inventory network Try our new Online Oring Store Standard and Metric Sizes

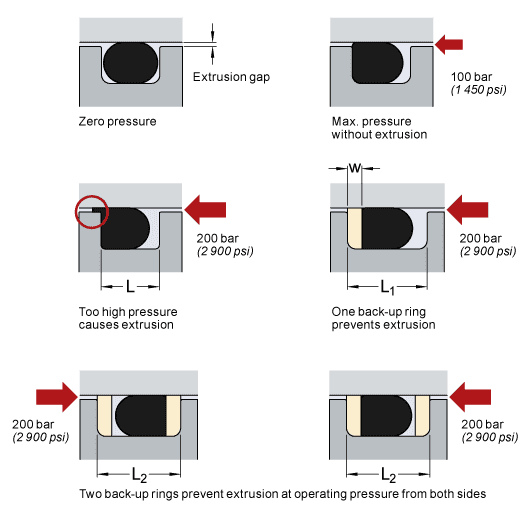

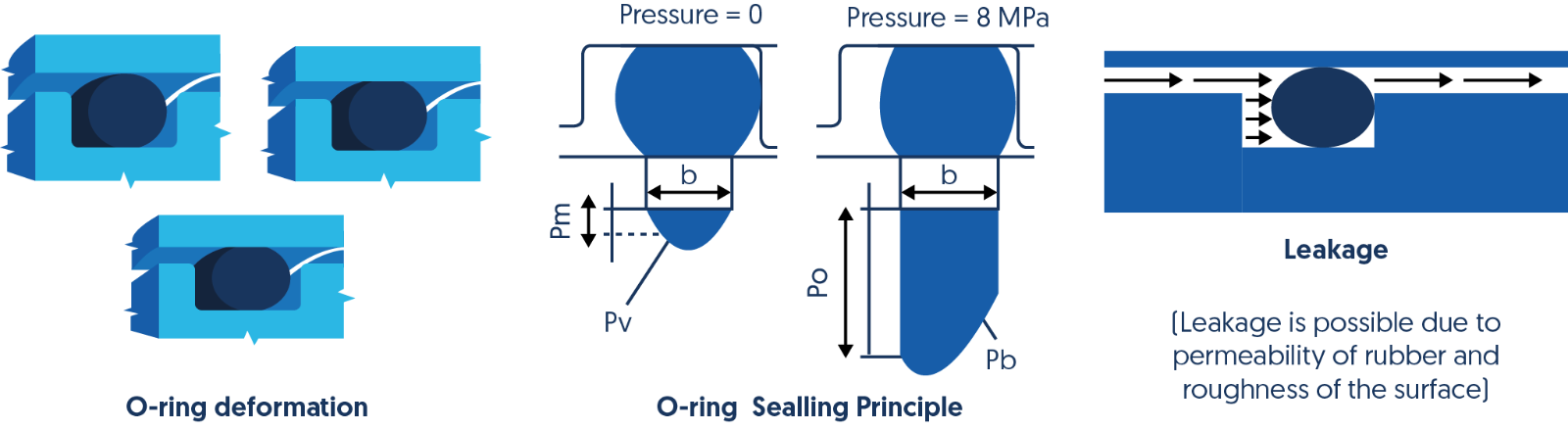

Welcome to our Size Charts Section, where you can download both imperial and metric ORing Size information In addition to standard imperial and metric sizes, Eastern Seals also supplies a wide variety of nonstandard sizes With over 8,000 different ORing sizes in stock, we have exactly what you are looking for and we can assure fast delivery of any size in large or smallStandard Oring Size 353 / 010 0139 / 0004 262 / 008 0103 / 0003 BS1806 British Standard Oring sizes (imperial) wwwperlastcom International Oring Standard Sizes PAGE 4 Millimeters Inches Internal Internal Cross Internal Internal Cross Diameter Diameter Section Diameter Diameter Section (mm) Tolerance / (mm) (inches) Tolerance / (inches) BS1806Groove dimensions for reciprocating and oscillating applications are the same Dynamic applications, due to the motion against the Oring, are more complicated than static applications Fluid compatibility must be more carefully scrutinized because a volume swell of more than % may lead to difficulties with high friction problems and only a minimum of shrinkage, at most 4%,

Fitting Thread Size Chart Printable

2

British Standard BS4518 Oring sizes (metric Orings) replaced by ISO3601 standard British Dowty Oring sizes German Standard DIN3771 metric Oring sizes replaced by ISO3601 standard Le Joint Français 'R' metric Oring sizes Japanese Standard JIS B 2401 (P, G and V) Oring sizes Get a quote for standard or custom sized OringsORing Size Chart This oring size chart displays the actual sizes represented by the AS568 Standard ORing size chart Included are 5 different CrossSections (0070 through 0275 inches), InsideDiameters ranging from 0029 to 155 inches and Boss Fitting Sizes (9XX series), including both an imperial and metric oring size chartSpliced and Vulcanized ORings ;

O Ring Groove Design Guides Engineering Quick Reference

O Ring Calculator Ceetak Sealing Solutions

MS ORING CHART SIZING (IMPERIAL SIZES) Part No marked in red are stock lines EMail sales@asapsparescomau Where Good Old Fashioned Service & Loyalty still Prevails Catalogue Index Use the chart below to determine the size All sizes are NOMINAL REFERENCE CHART ONLY Our Part No ID OD Width Our Part No ID OD Width MS 1/32 3/32 1/32 MSMetric oring groove designs vary greatly and choosing the right one for your application is important for maximum oring performance This metric oring groove design reference guide will help you find the right radius, backup, pressure and other oring dimensions for basic applications Once you find the exact metric oring you need, you can easily order online from the world'sThe proper oring size is a fundamental aspect of proper oring performance Whether your application conforms to US, Japanese JIS, British BS, or Common Metric sizing for orings, these oring size charts will help you locate the right oring size If the oring, quadring, xring or squarering you need doesn't fit these standards, custom and nonstandard products are

Untitled Document

1

Piston Groove Ø B Gland Groove Ø D Rod Ø C INCH ± mm ± INCH ± mm ± INCH STAT DYN STAT DYN ± 003 ± 003 ± 003 Only sizes marked * are suitable for dynamic applications HQ, EXPORTS CENTRAL WAREHOUSE Reginald Road, Smethwick, West Midlands, B67 5AS Tel 44 (0)121 429 8011 Fax 44 (0)121 434 3016 sales@barnwellcouk / export@barnwellcoukExample Calculations to Determine ORing Groove Dimensions Rod Seal Example Given Rod Diameter C = 500 Oring Cross Section W = 3/32 nominal Dynamic application No backups required Determine Oring size = AS (1/2 ID x 3/32 W nominal dimensions) Gland depth F = 090 000 001 (from chart) Groove width G = 144 /003 (from chart) Rod Gland D = C901 3/32 902 1/8 903 3/16 904 1/4 905 5/16 906 3/8 907 7/16 908 1/2 909 9/16 910 5/8 911 11/16 912 3/4 913 13/16 914 7/8 916 1 918 11/8 9 11/4 924 11/2 928 13/4

2

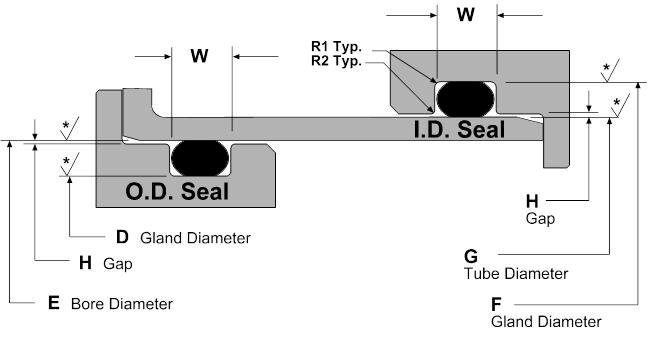

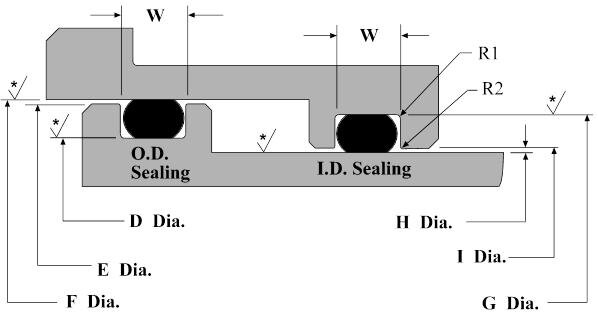

O Ring Groove Design Seal Design Inc

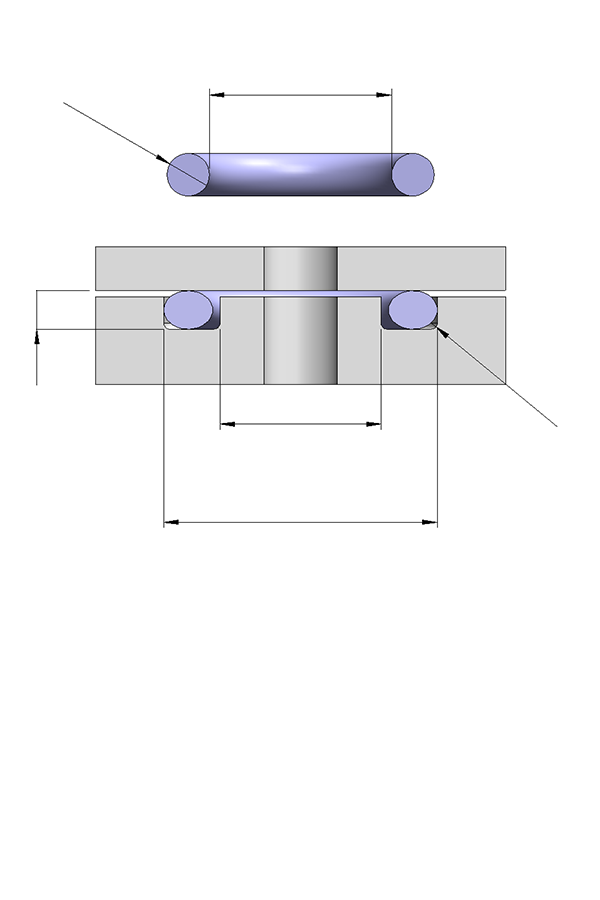

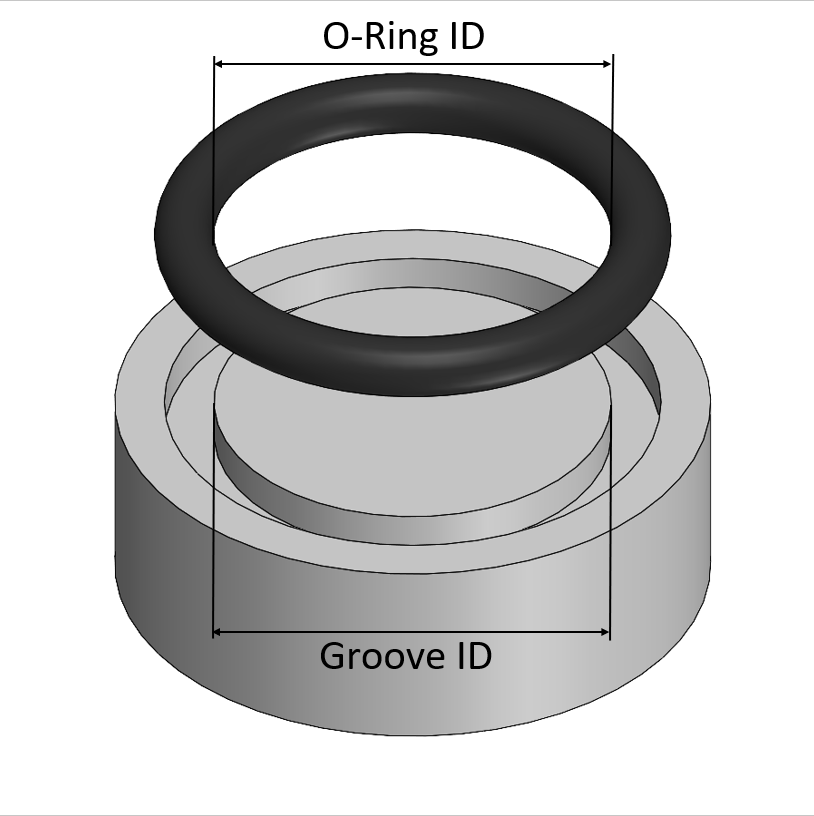

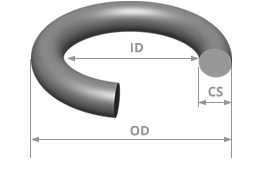

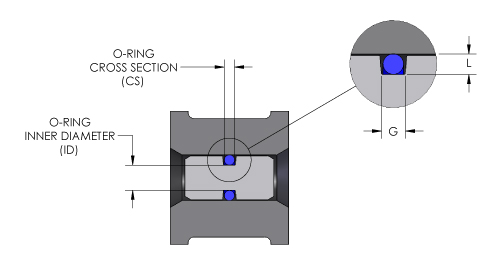

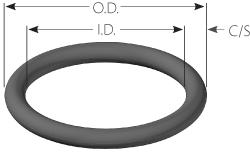

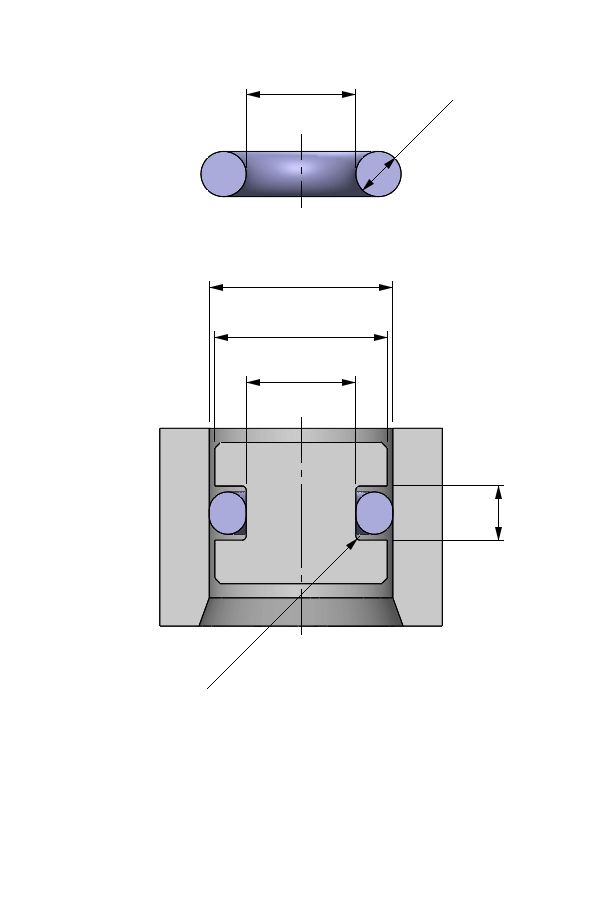

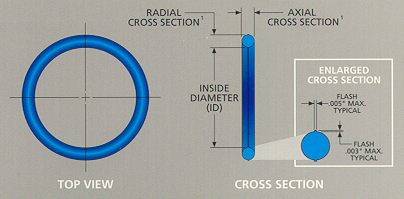

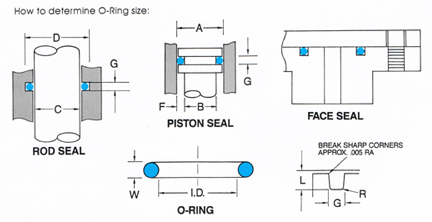

Two dimensions describe the size of an Oring its inside diameter (ID) and its crosssectional diameter (CS) (see Figure 1) Understanding Oring Sizes and Tolerances Standard Sizes The standard sizes used by Parco and the other major Oring manufacturers in the United States are defined by Aerospace Standard AS568B, Aerospace Size Standard for Orings That document,Call Us Seal & Design Canada Toronto, Ontario (416) Toll Free Headquarters Clarence,ORing groove and dimensions may be calculated as follows (please refer to chart above) Given Example Given Example Rod Diameter C = 500 Cylinder Bore A = 1000 Oring Cross Section W = 3/32″ nominal Oring Cross Section W = 1/8″ nominal Dynamic Application Static application No backups required No backups required Determine Determine Oring size = AS568

O Ring Design Considerations Marco Rubber Plastics Custom O Rings Supplier

O Ring Size And Installation Chart

ORing Reference AS568 Sizes AS568 ORing Size Reference Freudenberg and NOK Group 1 The Simrit ORing Design Quick Reference This design quick reference guide is intended for use in specifying Oring and groove dimensions for static applications with pressures less than 1500 psi The guidelines are for the nominal condition The minimum and maximum conditions should alsoThe ORing Store LLC ORing Groove Chart ORing Cord Stock OSK™ Assorted ORing Kits OSK™ ORing Repair Kits OSK™ Hydraulic Seal Kits OSK™ Air Nailer ORing Kits ORing Lube ORing Tools AS568 ORings (Inch) Metric ORings (mm) OSK Pool, Spa & Pump Orings Hydraulic Seals Inch ORing Glue & Thread Sealant Vulcanized ORings ORing Splice Kits & Tools92 Parker Hannifi n Corporation • ORing Division 2360 Palumbo Drive, Lexington, KY Phone (859) † Fax (859) wwwparkeroringscom Sizes Parker ORing Handbook Sizes

O Ring Groove Dimensions Pdf Dimensions Ring Joint Facings Asme B16 5 Pressure Class 150

O Rings An Overview Sciencedirect Topics

Hardness All Ring SizesHRC 4252 Free Diameter & Ring Measurement with Section BB Housing Diameter & Groove Dimensions Material SAE Snap Ring, Internal, Inch Designed for needle bearings, once installed in the groove of a housing/bore, the portion of the ring protruding from the groove holds an assembly in place For the most uptodate specifications, onlineMETRIC IMPERIAL IMPERIAL BS Reference Alternative References ID Section OD ID Section OD ID OD BS 548Use our oring size chart and calculator to find the AS568 or metric sizing of standard size HNBR, Viton, and other orings Go to Navigation Go to Content Request A Quote Contact Us Call Us Menu Products ORings Standard ORings;

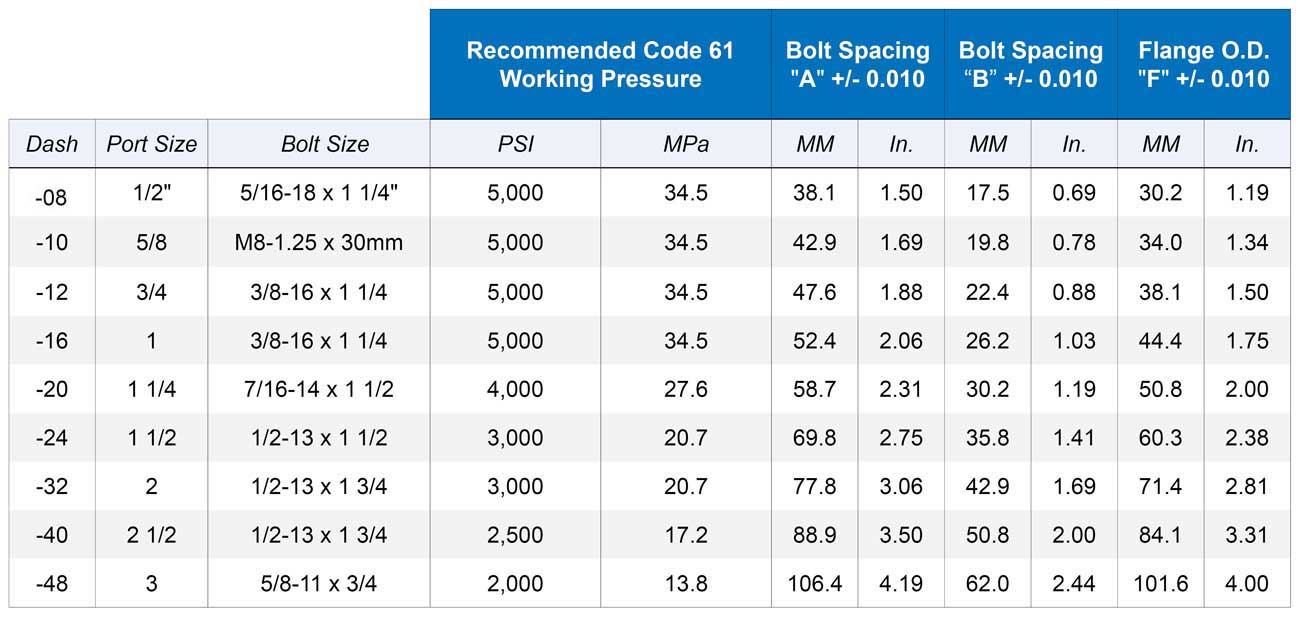

Sae Flanges Code 61 Code 62 Code 62c Ryco Hydraulics

Wire Gauges And Ring Sizes Theringlord Com

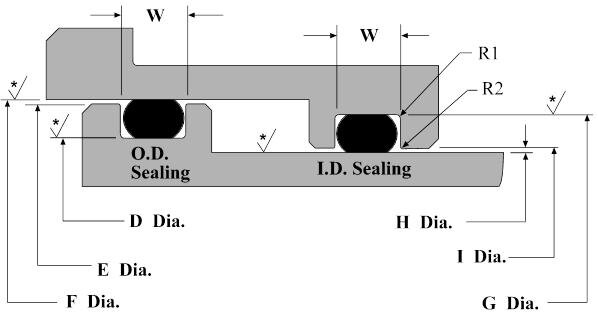

h Groove style B i Screw threads SAE J1453 ORFS Groove and orfs o ring sizes chart as follows Dimensions in millimetres Oring Surface B d f i 1 i 5 d 4 Tube outside diameter Thread a Outside diameter Inside diameter nom tol ± 0,4 min nom tol min max 6 9/1618 UNF 2,4 ± 0,3 10 9 7,65 ± 0,16 11,08 6,1The AS Oring Size Chart has a column that shows the Nominal Size alongside the Actual Size Originally the nominal size was just for a listing of the approximate fractional dimensions of the Oring Prior to the common use of dial calipers many people called out a 1 inch by 11/4 rt = Oring, this was a dash 214 Oring They used to also use these fractional dimensions as the gland sizeAnd 0060" for sizes 8" OD and above measured from true square line COLUMN 3 Gasket seat The pipe surface shall be free from indentations, roll marks, and projections from the end of the pipe to the groove, to provide a leaktight seal for the gasket All loose paint, scale, dirt, chips, grease and rust must be removed It continues to be Victaulic's first

Metric O Ring Groove Design Reference Guide

O Ring Design Considerations Marco Rubber Plastics Custom O Rings Supplier

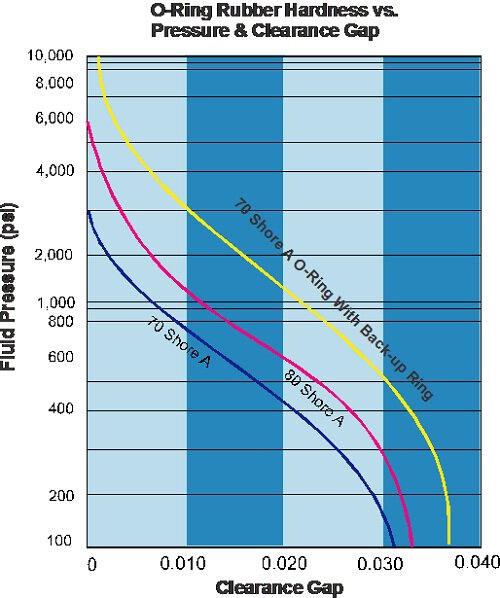

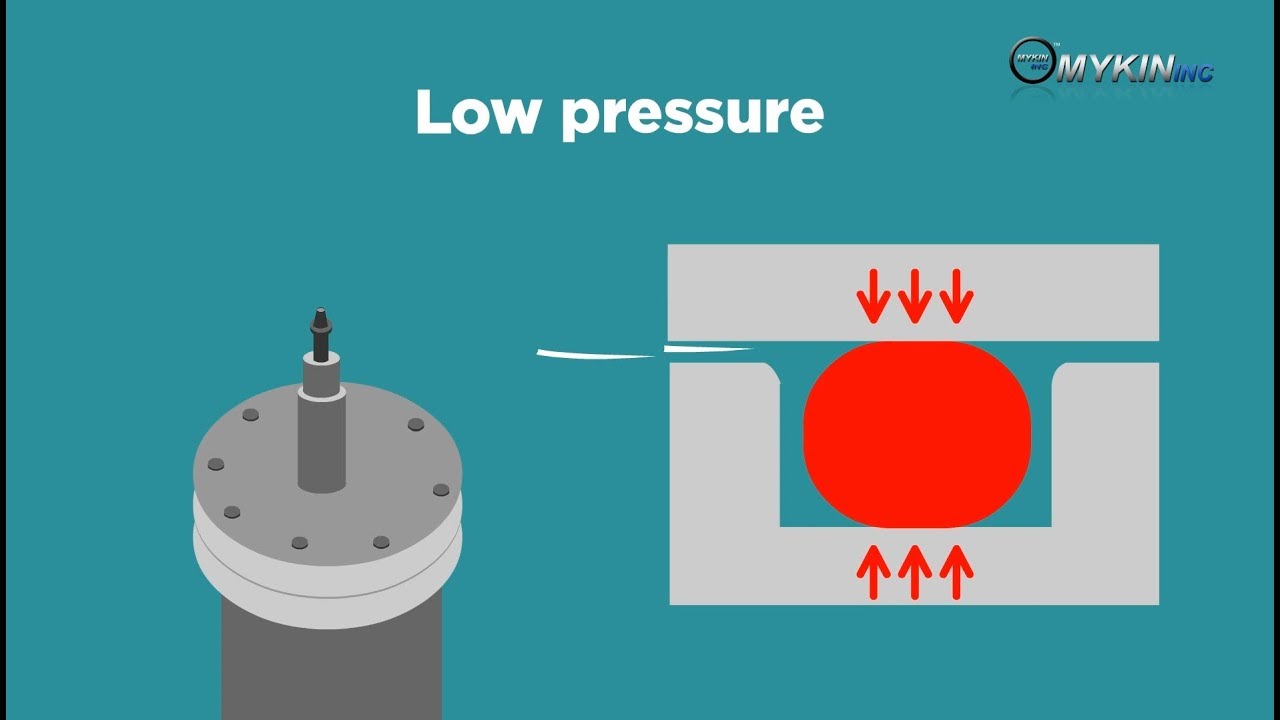

The ORing should be installed in a groove in the body, the depth of the groove should be such that the ORing projects a little above the groove When the shaft or the rod is mounted, the ORing will be compressed by 1015%, so that an effective amount of sealing will be obtained C The application of ORings for sealing rotating parts is notThe groove must be designed to accommodate not just the o'ring size, but also its intended usage;Be it dynamic or static operation, radial or axial loading, vacuum or high pressure The following information is a guide for o'ring groove dimensions for both static and reciprocating dynamic applications The info is based on 70 Shore A Durometer hardness only Surface Finish Generally

O Ring Groove Chart

O Ring Groove Design Standard As568b Seal Design Inc

Step 3 Choose the correct hardness for your application by going to our rubber hardness chart Step 4 Design and dimension the groove that your Oring will go into by researching our Oring Groove Design guide Step 5 Choose a standard size AS568 Oring using this Oring Size Chart Otherwise contact us and we can custom mold any size orO'ring Sizing Sealing Australia stock a wide variety of standard and nonstandard o'ring sizes For standard sizing, please see tables below for sizing and tolerances Imperial sizes British Standard BS1806 / American Aerospace Standard AS568A, SAE boss seals and extended range of imperial sized o'rings BS1806/AS568AOring As shown in Table 2, pressed steel cages are generally used for most deep groove ball bearings Larger size deep groove ball bearings, and bearings operating at high rotational speeds often utilize a machined metallic cage 3 Other deep groove ball bearing enhancements 31 Bearings with snap rings A snap ring grove or snap ring groove with snap ring combination are

2

Sae Flange O Ring Code 61 Dimension Charts Knowledge Yuyao Jiayuan Hydraulic Fitting Factory

ORing Size Guide The safe choice for seals and moulded parts used in hydraulics, pneumatics, precision engineering, food/medical industries, oil & gas, valve & pump and aerospace M Seals specialises in seals for industrial use;The housing dimensions for static radial sealing Orings are listed in the size lists Housing groove edges All housing groove edges should be smoothed and rounded off ( fig 1 , fig 2 ) to r = 0,1 to 0,2 mm (0004 to 0,008 in)ORing Seal Ring Size AS568A Dimensions Rubber Compound Note The Rod and Bore columns listed in the following table do NOT indicate a rod/bore combination for a specific seal number To use the table, first determine the proper seal size by locating the rod or the bore size on which you are sealing The seal groove diameter can then be calculated as indicated, starting on page 610

Ruander Com Quick O Ring Groove Design Guide

O Ring Grooves

Chart 50 inch & metric sizes 1316 'O' rings for pipe fittings 16 Aerospace sizes to BS ISO 17 Chart 72 metric sizes 2122 Chart inch sizes 23 Nonstandard sizes 24 Complementary products Coloured materials 25 'O' ring cord 25 Commercial quality 'O' rings 25 'O' ring kits 26 Special packaging & kits 26 'OAlso provides an overview of international sizes and standards, and compatibility data for fl uids, gland design recommendation charts troubleshooting utility pressure calculator • ParZap inventory management • Worldwide distribution • Extensive product literature, test reports and much more 5 t A E II Parker Hannifi n Corporation • ORing Division 2360 Palumbo DriveSection 3—Global ORing Size Reference Guide Inch and metric dimensions with tolerances for most major, global oring size standards can be found in Section Three Orings can be supplied in most of these sizes without a tooling charge Dichtomatik is also tooled on a large

O Rings And Back Up Rings Skf Skf

How To Properly Size An O Ring Global O Ring And Seal

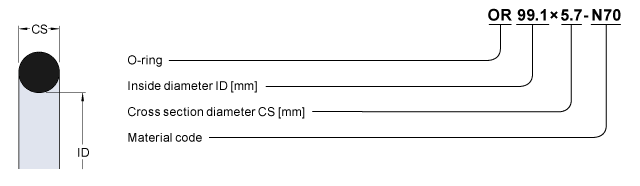

Based on the cross section (CS) of your Oring, you will choose the corresponding Oring groove depth and Oring groove width dimensions The Oring inner diameter (ID) should also stretch approximately 5% over your groove or gland If you have a custom Oring size that does not appear on this chart, contact us directly and we can help you size your Oring gland designThese oring sizes are unique to Japan's automotive, semiconductor, and manufacturing industries JIS ORing Groups Aerospace Group 367 sizes and follows ISO very closely (with a few extra sizes) Each size is designated by its dimension ID × crosssection Subsequent to the dimension, the letter "A" is appended to indicate useDimensions of orings in one ordering number How to Determine ORing Size* For Sequence in Ordering 1 Size (catalog number) 2 Durometer and material 3 Quantity Example 110 – 70SLR – 10,000 (size – durometer, material and color – quantity) Outside diameter (OD) is for reference only ORings are specified by ID and cross section

O Ring Groove Design Global O Ring And Seal

1

(b) Use Class 600 sizes NPS 1/2 to NPS 3½ for Class 400 (c) Use Class 1500 in sizes NPS 1/2 to NPS 2½ for Class 900 (d) Ring joint gasket materials shall conform to ASME B16 (e) The edge (periphery) of each ring joint flange shall be marked with the letter R and the corresponding ring groove number NotesThe Oring to roll slightly in its groove under certain conditions of motion, but the rolling action is not necessary for normal operation of the seal The shape of the groove is unimportant as long as it results in proper squeeze of the Oring Groove dimensions are shown in the tables beginning on page 138 The groove depth is measured

O Rings And Seals Flat Rubber Seal Ring O Ring Seal High Temperature O Rings Fuel O Rings Freudenberg Fst

2

British O Ring Size Chart Bs British Standard O Ring Sizes

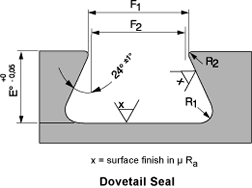

Standard Dovetail Grooves Dovetail Groove Engineering Design Guide

2

2

O Ring Size Chart For U S Metric Standard Sizes

O Ring Groove Design Seal Design Inc

2

O Ring Groove Design O Ring Groove Dimensions Mykin Inc

Sae Code 61 O Ring Groove Dimensions Knowledge Yuyao Jiayuan Hydraulic Fitting Factory

Internal Retaining Snap Ring Sizes And Groove Design Chart Engineers Edge

O Ring Groove Design Standard As568b Seal Design Inc

O Ring Size Chart For U S Metric Standard Sizes

2

Buy O Rings Seals Custom Molded Rubber Engineered Plastic All Seals

Engineering Basics Guide To O Rings Eriks Shop Nl

O Ring Wikipedia

O Ring Design O Ring Design Guide O Ring Seal Design Mykin Inc

O Ring Groove Design Daemar Inc

Technical Handbook O Ring

1

O Ring Groove Design Global O Ring And Seal

2

2

O Ring Seals Roy Mech

2

Designing Axial Static O Ring Grooves To Industry Standards Grabcad Tutorials

O Ring Groove Design Guides Engineering Quick Reference

Ring Seal An Overview Sciencedirect Topics

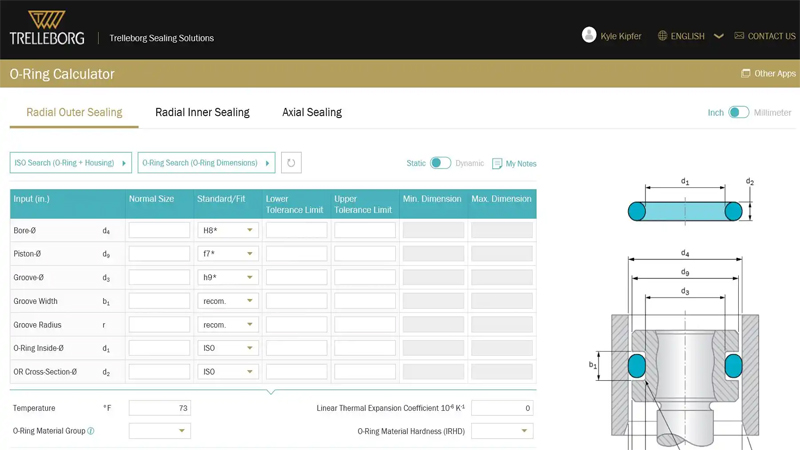

O Ring Calculator Trelleborg Sealing Solutions

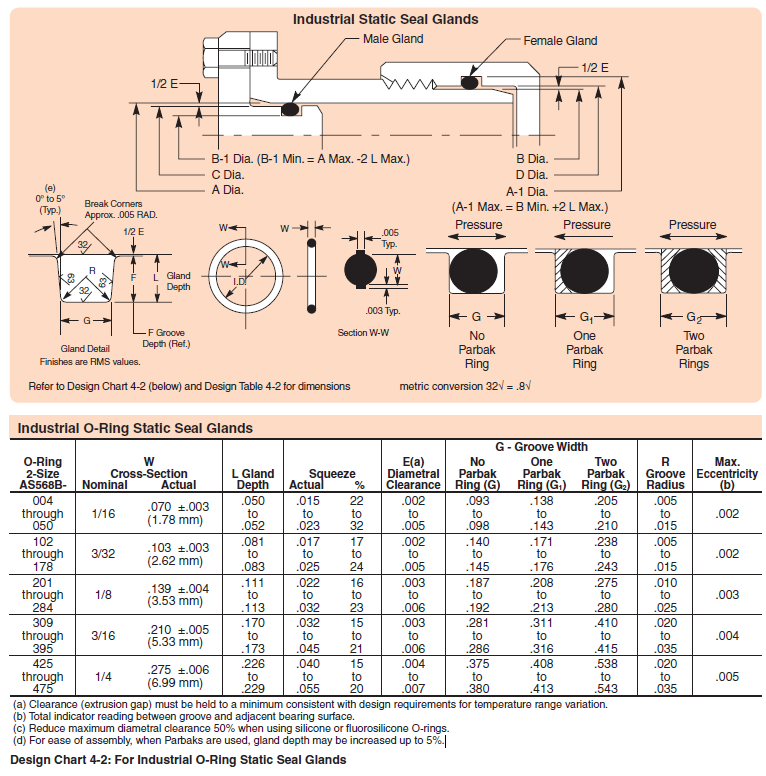

Static O Ring Design Chart Marco Rubber Plastics Custom O Rings Supplier

O Ring Groove Design Guides Engineering Quick Reference

Viton O Rings Viton Gaskets Viton Seals

Ring Seal An Overview Sciencedirect Topics

O Ring Wikipedia

Dynamic O Ring Design Chart Marco Rubber Plastics Custom O Rings Supplier

1

Designing Axial Static O Ring Grooves To Industry Standards Grabcad Tutorials

2

2

O Ring Groove Dimensions Calculator Precision Polymer Engineering

2

O Ring Calculator Ceetak Sealing Solutions

Learn How To Measure O Rings The Right Way O Ring Size Chart

O Rings And Back Up Rings Skf Skf

Sae J1453 O Ring Face Seal Groove Size Chart Knowledge Yuyao Jiayuan Hydraulic Fitting Factory

O Ring Groove Design Global O Ring And Seal

O Ring Size Chart For U S Metric Standard Sizes

O Ring Sizes And Dimensions Seal Design Inc

Designing Axial Static O Ring Grooves To Industry Standards Grabcad Tutorials

O Ring Cross Section O Ring Groove Design Data

Groove Design O Ring Seals Minnesota Rubber Plastics

Ring Seal An Overview Sciencedirect Topics

2

Metric O Ring Groove Design Reference Guide

2

Sae J1453 O Ring Face Seal Groove Size Chart Knowledge Yuyao Jiayuan Hydraulic Fitting Factory

Dcr Rotor Clip Company Pdf Catalogs Technical Documentation Brochure

2

Sae Code 61 O Ring Groove Dimensions Knowledge Yuyao Jiayuan Hydraulic Fitting Factory

O Ring Groove Design Guides Engineering Quick Reference

Designing Axial Static O Ring Grooves To Industry Standards Grabcad Tutorials

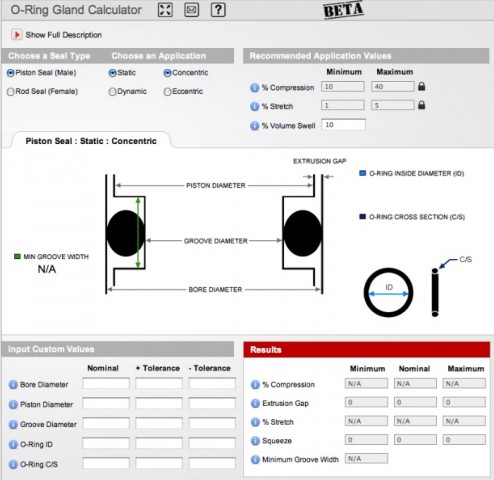

New Gland Calculator Tool At Applerubber Com Official Apple Rubber Blog

Designing Axial Static O Ring Grooves To Industry Standards Grabcad Tutorials

O Ring Groove Design Sealing Australia

Sae J518 Code 61 And Code 62 4 Bolt Flanges

2

O Rings O Yeah How To Select Design And Install O Ring Seals Youtube

Groove Design O Ring Seals Minnesota Rubber Plastics

O Ring Groove Design Global O Ring And Seal

O Ring Groove Design Standard As568b Seal Design Inc

O Ring Size Charts As568 Metric Global O Ring And Seal

O Ring Groove Design Metric Seal Design Inc

Designing Axial Static O Ring Grooves To Industry Standards Grabcad Tutorials

O Ring Groove Dimensions Pdf Dimensions Ring Joint Facings Asme B16 5 Pressure Class 150

O Ring Groove Design

2